概述

该阀门主要用于供水、供热及制酸等具有强氯化性的介质的系统里,

常配作为锅炉附件等。

概述

该阀门主要用于供水、供热及制酸等具有强氯化性的介质的系统里,

常配作为锅炉附件等。由于外型轻巧,结构简单,弹簧装置加速了阀掰的关闭,

可适当的消除水锤。一般适用于对安装空间有限制的场所。

Overview

This valve is mainly used in the system carrying strong oxidative mediums in

water and heat supply and acid making etc

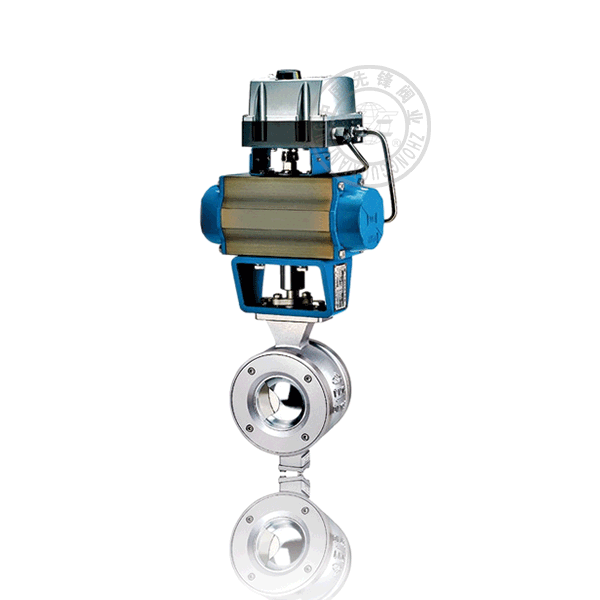

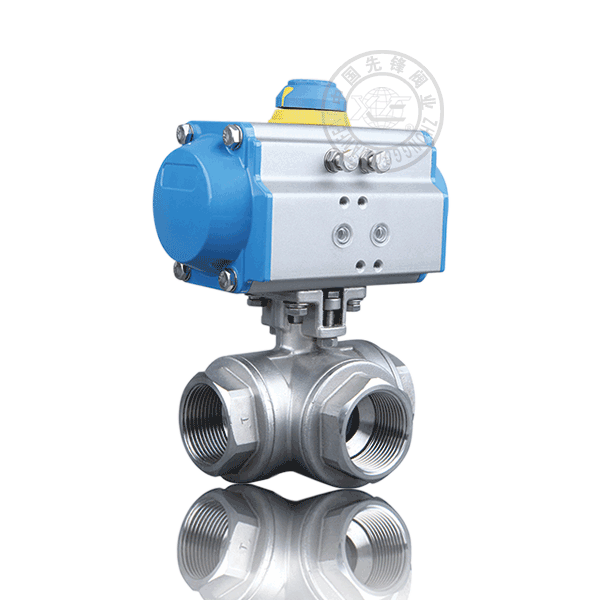

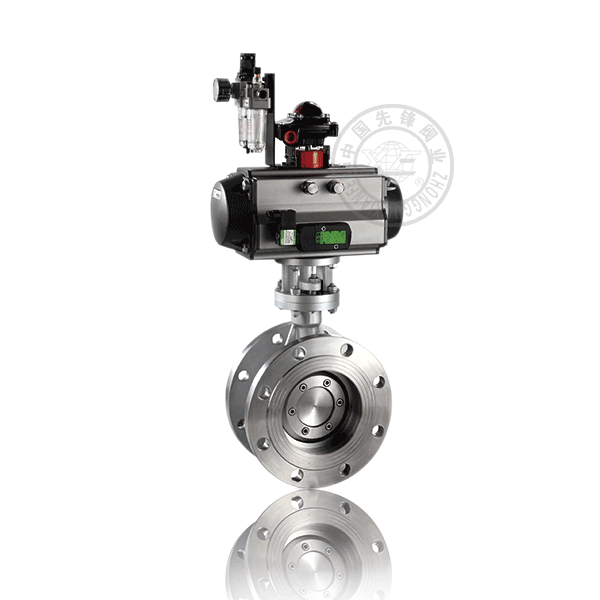

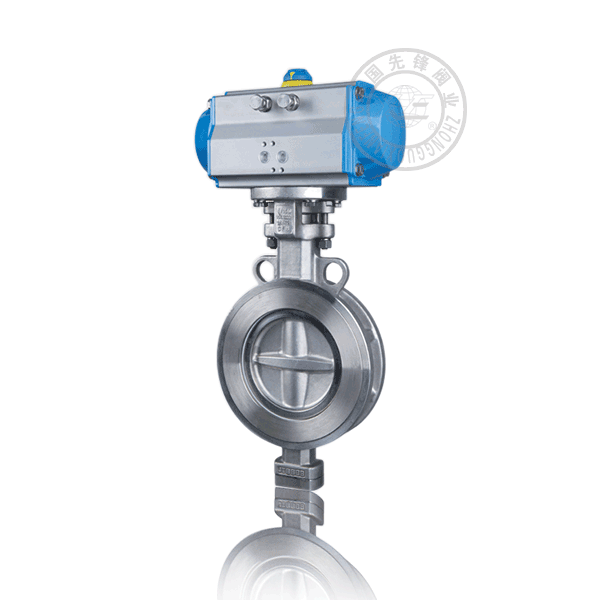

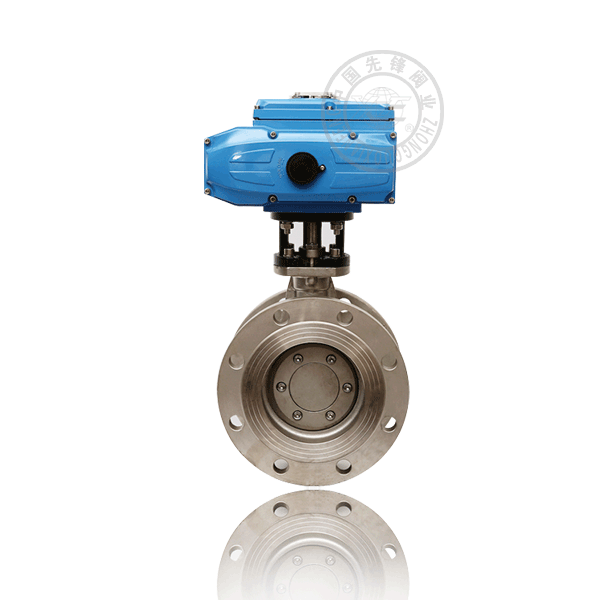

产品图:

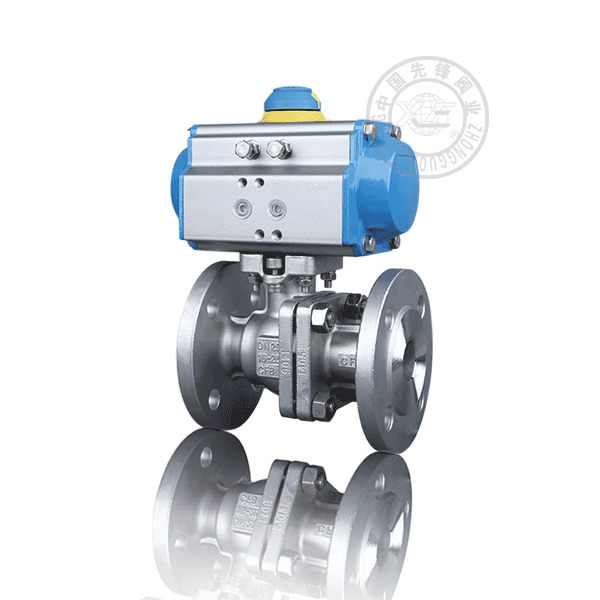

可选配件:

|

概述 该阀门主要用于供水、供热及制酸等具有强氯化性的介质的系统里, 常配作为锅炉附件等。由于外型轻巧,结构简单,弹簧装置加速了阀掰的关闭, 可适当的消除水锤。一般适用于对安装空间有限制的场所。 Overview This valve is mainly used in the system carrying strong oxidative mediums in water and heat supply and acid making etc., usually used as accessories for boilers. Provded with exquisite profile and simple structure, its spring device functions to speed up the close of disc to eliminate water hammer. This valve is applicable for space-restricted locations. |

主要零件材质Main Parts and Materials

|

主要性能参数Main

|

型号 Type |

公称压力(MPa) Nominal Pressure |

试验压力Ps(MPa) Test Pressure PS |

工作温度(℃) Working Temperature(℃) |

工作压力P(MPa) Working pressure |

适用介质 Applicable Medium |

|

|

壳体Shell |

密封Seal |

|||||

|

H71H-C |

1.0 |

1.5 |

1.1 |

≤200 |

1.0 |

水、蒸汽、油品、 硝酸及尿素等 氧化性腐蚀性介质 Water,steam,oil,oxygen, Such as nitric acid and Urea,etc.Melting Corrosivity medium |

|

H71W-P |

1.6 |

2.4 |

1.76 |

1.6 |

||

|

|

2.5 |

3.8 |

2.8 |

2.5 |

||

|

H71W-R |

4.0 |

6.0 |

4.4 |

4.0 |

||

主要外形尺寸及连接尺寸Main External Dimensions and Sonnecting Dimensions

|

公称通径(mm) Nominal Diameter |

L |

D |

重量(kg) weight |

D |

重量(kg) weight |

D |

重量(kg) weight |

D |

重量(kg) weight |

|

1.0MPa |

1.6MPa |

2.5MPa |

4.0MPa |

||||||

|

15 |

16 |

53 |

0.3 |

53 |

0.3 |

53 |

0.3 |

53 |

0.3 |

|

20 |

19 |

63 |

0.5 |

63 |

0.5 |

63 |

0.5 |

63 |

0.5 |

|

25 |

22 |

73 |

0.7 |

73 |

0.7 |

73 |

0.8 |

73 |

0.8 |

|

32 |

28 |

84 |

1.1 |

84 |

1.1 |

84 |

1.3 |

84 |

1.3 |

|

40 |

32 |

94 |

1.14 |

94 |

1.5 |

94 |

1.6 |

94 |

1.8 |

|

50 |

40 |

109 |

2.1 |

109 |

2.2 |

109 |

2.3 |

109 |

2.6 |

|

65 |

46 |

129 |

2.9 |

129 |

3.2 |

129 |

3.3 |

129 |

3.6 |

|

80 |

50 |

144 |

3.7 |

144 |

4.0 |

144 |

4.4 |

144 |

4.8 |

|

100 |

60 |

164 |

4.8 |

164 |

5.2 |

170 |

5.6 |

170 |

5.9 |

|

125 |

90 |

194 |

7.8 |

194 |

8.6 |

198 |

9.2 |

198 |

10 |

|

150 |

106 |

220 |

10.6 |

220 |

11.6 |

228 |

12.5 |

228 |

13.5 |

|

200 |

140 |

272 |

/ |

272 |

/ |

285 |

/ |

290 |

/ |

|

250 |

165 |

327 |

/ |

327 |

/ |

340 |

/ |

350 |

/ |

|

300 |

178 |

377 |

/ |

385 |

/ |

403 |

/ |

/ |

/ |

|

350 |

190 |

44 |

/ |

446 |

/ |

460 |

/ |

/ |

/ |

|

400 |

216 |

491 |

/ |

498 |

/ |

517 |

/ |

/ |

/ |

sales@xianfengvalve.com

sales@xianfengvalve.com

在线咨询

在线咨询