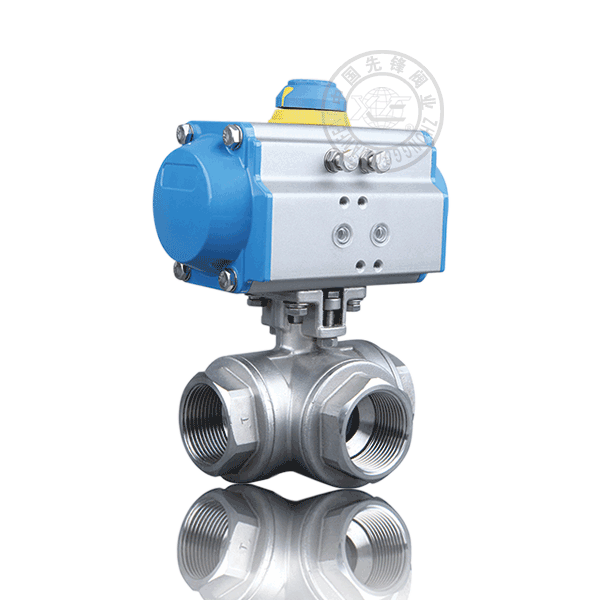

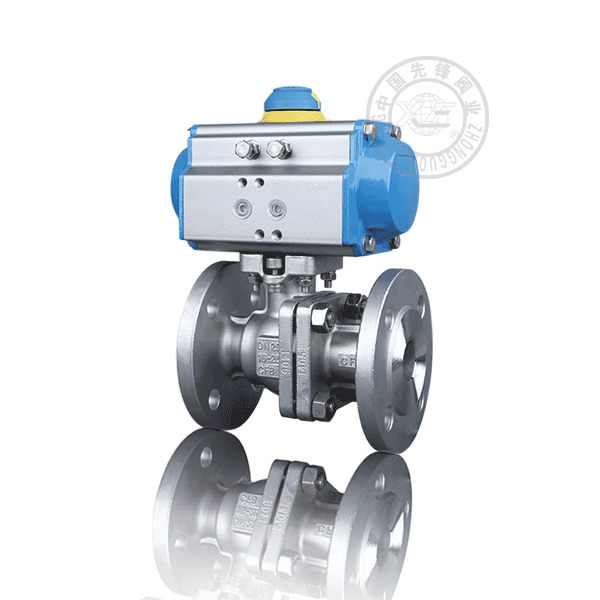

产品特点

1、本产品所有部件均为锻件。

2、采用下装式阀杆,设置倒密封结构,确保填料处可靠密封及防止阀杆脱出。

3、采用镶嵌式阀座。阀座背后设置O型圈,确保介质不外漏。

Features

1、All the components are forged ones.

2、Lower-Ioading Stem and backward sealing construction

have b-een setup forpositive sealing at stuffing position

and backingout otecting of the handle.

3、lnterbedded valve seat is applied on whose back Oring

is a-lso mounted for avoiding the leakage of medium.

主要零件材料Main Parts and Materials

零件名称

Accessory name

材质 Material

GB

ASTM

阀体、阀盖

Body,Bonnet

WCB

A216-WCB

密封圈

Sealing ring

尼龙Nylon

尼龙Nylon

球体 Ball

1Cr18Ni9Ti

SS 304

阀座、阀杆

Seat,Stem

2Cr13

A246-416

O形圈 O ring

橡胶RUBBER

橡胶RUBBER

双头螺栓

Dual-head bolt

35CrMoA

A193-B7

主要性能规范Main performance Specifications

公称压力

Nominal pressure

16

32

MPa

强度试验压力PT

Strength test pressure

24

48

MPa

低压密封试验力

Low pressure sealing test

0.6

MPa

高压密封试验力

High pressure sealing test

17.6

35.2

MPa

适用介质

Applicable medium

水、油品、蒸汽

Water,Oil,Steam

适用温度

Applicable temperature

-40~80℃

主要连接及外形尺寸Main conn ection and externaldimensions(mm)

|

公称压力 PN(Mpa) Nominal diameter |

公称通径 DN(mm) Nominal pressure |

主要尺寸(mm)Main dimension |

||||||||||||||

|

L |

L1 |

D |

D1 |

H |

W |

M |

D2 |

b |

Z-φd |

|||||||

|

法兰 Flange |

对焊 Butt-welding |

法兰 Flange |

对焊 Butt-welding |

法兰 Flange |

对焊 Butt-welding |

法兰 Flange |

对焊 Butt-welding |

法兰 Flange |

对焊 Butt-welding |

法兰Flange |

||||||

|

16.0 |

10 |

210 |

150 |

52 |

60 |

95 |

90 |

60 |

18 |

77 |

58 |

220 |

M24x2 |

18 |

20 |

3-φ18 |

|

15 |

230 |

170 |

62 |

70 |

95 |

100 |

60 |

23 |

85 |

62 |

220 |

M24x2 |

20 |

20 |

3-φ18 |

|

|

20 |

240 |

190 |

73 |

80 |

105 |

110 |

68 |

29 |

94 |

75 |

250 |

M33x2 |

28 |

20 |

3-φ18 |

|

|

25 |

260 |

205 |

77 |

95 |

105 |

115 |

68 |

36 |

100 |

80 |

250 |

M33x2 |

28 |

22 |

3-φ18 |

|

|

32 |

300 |

230 |

100 |

110 |

115 |

150 |

80 |

43 |

120 |

96 |

300 |

M42x2 |

38 |

24 |

4-φ8 |

|

|

40 |

|

260 |

110 |

120 |

165 |

170 |

115 |

49 |

150 |

111 |

400 |

M52x2 |

48 |

30 |

6-φ26 |

|

|

50 |

400 |

330 |

130 |

140 |

165 |

200 |

115 |

61 |

165 |

128 |

450 |

M64x3 |

58 |

32 |

6-φ26 |

|

|

65 |

490 |

360 |

140 |

150 |

200 |

225 |

145 |

80 |

180 |

180 |

500 |

M80x3 |

74 |

40 |

6-φ29 |

|

|

80 |

580 |

380 |

150 |

160 |

225 |

270 |

170 |

105 |

200 |

200 |

600 |

M100x3 |

94 |

50 |

6-φ33 |

|

|

100 |

620 |

430 |

178 |

188 |

260 |

320 |

195 |

115 |

245 |

245 |

800 |

M125x4 |

115 |

60 |

6-φ36 |

|

|

32.0 |

10 |

210 |

150 |

52 |

60 |

95 |

90 |

60 |

18 |

77 |

77 |

220 |

M24x2 |

18 |

20 |

3-φ18 |

|

15 |

230 |

170 |

62 |

70 |

105 |

100 |

68 |

23 |

85 |

85 |

220 |

M33x2 |

28 |

20 |

3-φ18 |

|

|

20 |

240 |

190 |

73 |

80 |

105 |

110 |

68 |

29 |

94 |

94 |

250 |

M33x2 |

28 |

20 |

3-φ18 |

|

|

25 |

260 |

205 |

77 |

95 |

115 |

115 |

80 |

36 |

100 |

100 |

250 |

M42x2 |

35 |

25 |

4-φ18 |

|

|

32 |

300 |

230 |

100 |

110 |

135 |

150 |

95 |

43 |

120 |

120 |

300 |

M52x2 |

41 |

30 |

4-φ22 |

|

|

40 |

350 |

260 |

110 |

120 |

165 |

170 |

115 |

49 |

150 |

150 |

400 |

M64x3 |

47 |

35 |

6-φ26 |

|

|

50 |

400 |

330 |

130 |

140 |

200 |

200 |

145 |

61 |

165 |

165 |

450 |

M80x3 |

70 |

40 |

6-φ29 |

|

|

65 |

490 |

360 |

140 |

150 |

225 |

225 |

170 |

80 |

180 |

180 |

500 |

M100x3 |

90 |

50 |

6-φ33 |

|

|

80 |

580 |

380 |

150 |

160 |

260 |

270 |

195 |

105 |

200 |

200 |

600 |

M125x4 |

112 |

55 |

6-φ36 |

|

|

100 |

620 |

430 |

178 |

188 |

300 |

320 |

235 |

118 |

245 |

245 |

800 |

M155x4 |

135 |

65 |

8-φ36 |

|

sales@xianfengvalve.com

sales@xianfengvalve.com

在线咨询

在线咨询