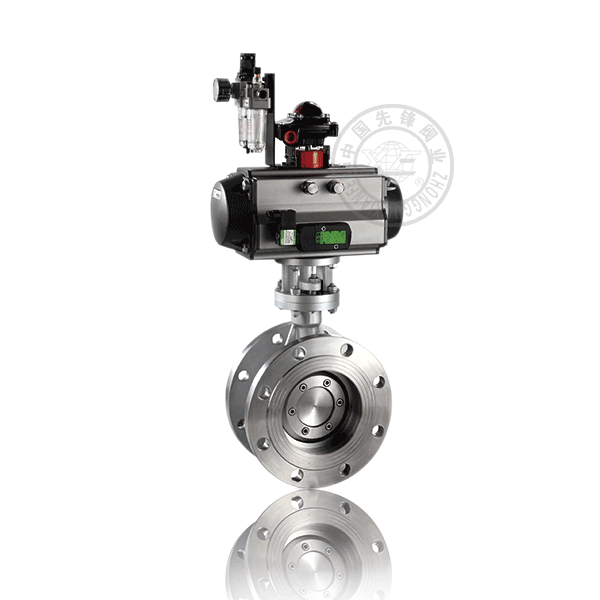

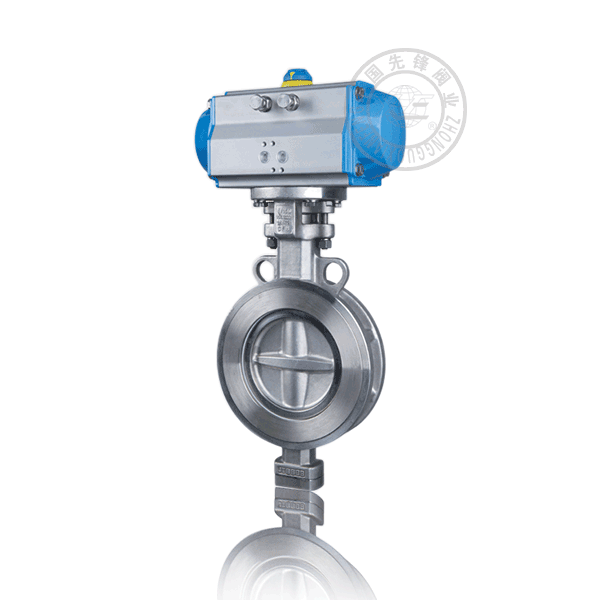

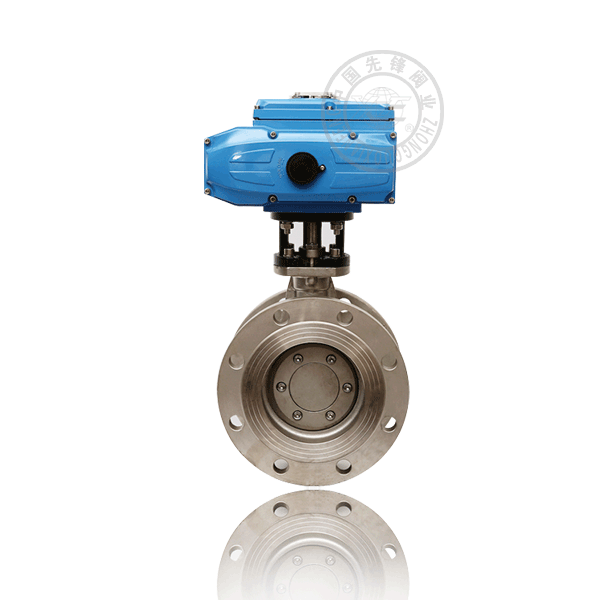

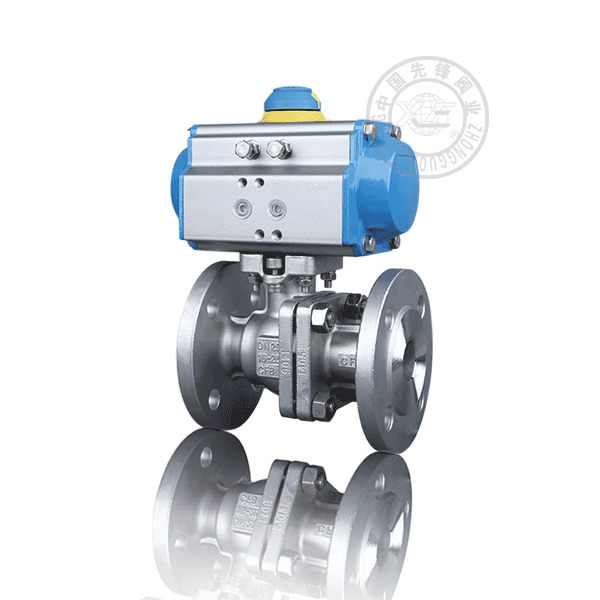

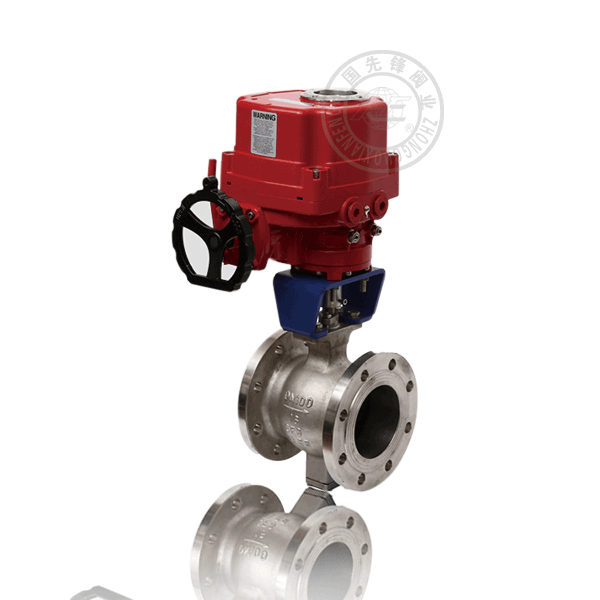

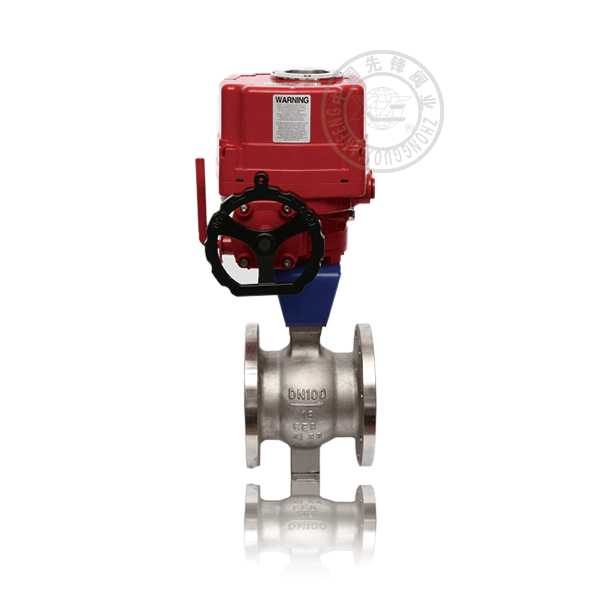

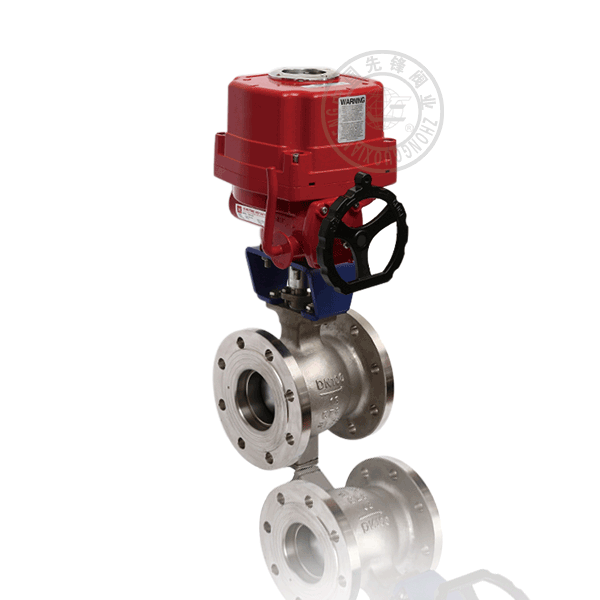

偏心半球阀的特点

偏心半球阀的特点之一启闭无磨擦.由于采用偏心结构.阀门在关闭的过程中.球体逐渐靠近阀座,到关闭位置完全接触;在开启时球体离开密封位置即可完全脱开.开启扭矩小

Biased half ball valve characteristic

Biased one of half ball valve characteristics opens shuts, because uses the eccentric structure, the valve in the shuting down process, the spheroid gradually approaches the valve seat, completely contacts to the off-position;

|

偏心半球阀的特点 偏心半球阀的特点之一启闭无磨擦.由于采用偏心结构.阀门在关闭的过程中.球体逐渐靠近阀座,到关闭位置完全接齄;在开启时球体离开密封位置即可完全脱开.开启扭矩小;第二个特点是密封面可实现自清洁.球体离开阀座时,介质可冲去密封面上的积聚物.对于易结晶介质.球体在关闭过程中可切除介质结晶达到密封的目的.避免了其它阀门无法开关的弊端;第三个特点是密封严紧,球体、阀座是双金属.采取不同工艺.密封面可组合成防腐、耐磨等各种类型.满足不同工况的需求,密封是球面线接触,靠二维偏心实现零泄漏。 |

Biased half ball valve characteristic

Biased one of half ball valve characteristics opens shuts, because uses the eccentric structure, the valve in the shuting down process, the spheroid gradually approaches the valve seat, completely contacts to the off-position; When opening the spheroid leaves seals the position the completely to withdraw, opens the torque to be small; The second characteristic is the packing surface may realize from cleanly, when the spheroid leaves the valve seat, the medium may flush away in the packing surface the agglomeration, regarding is easy to Cfystallize the medium, the spheroid may excise the medium crystallization in the closure process to achieve the seal the goal, avoided other valves being unable the switch malpractice;The third character-istic is the seal close, the spheraid, the valve seat are the bimetal, adopts thedifferent craft, the packing surface may the group synthesize the anticarrosion, be wear-resisting and so on each kind of type, satisfies the different operating made the demand, the seal is the spherical surface, depends on two-dimensional biased realizaton zero to divulge.

|

|

主要设计参数Main design variable 公称通径:2”~28”DN50~700 公称压力:Calss 150~60Lb, PNl.O~lO.OMPa 阀体材质:WCB, CF8, CF8M 球体:硬密封:WCB/CF8CF8M+STL 软密封:CF8/CF8M 阀座:硬密封:A105/F304/F316+STL 软密封:PTFE, PPL 工作温度:硬密封:-40℃~425℃ 软密封:-28~250℃

采用的主要标准Uses main standard 设计制造按API 6D GB/T12237-1989 试验和检验按API 598 JB/T9092-1999 法兰尺寸按ANSI B16.5 GB/T9113-2000 JG/T79-1994 HG20592-1997 绪构长度按HT-2000

|

|

|

工作原理 偏心半球阀由阀杆带动球体绕旋转中心A转动时,球体由B点移动C点,此时相对阀门中心O,从B到C的轨迹为一凸轮状偏心,向下进入阀座使阀门关闭保持密。该阀由于存上上述凸轮原理.阀门关闭件从开启到关闭过程中,作用在阀座上的力逐渐增加,即关闭件表面与阀座由完全脱离至接触,并逐渐增大密封比压.直至完全密封.反之亦然。这就大大改善了以往球阀的密封状态和密封效果,适合高温高压及易结晶磨损严重的场合使用。 |

Principle of work The biased half ball valve when circles the center of rotation A rotation by the valve lever impetus spheroid, the spheroid by B moves C, this time relative valve center O, from B to the C path is a cam shape bias, enters the valve seat toward un-der to cause the valve closure maintenace seal. This valve because has above cam principle, the valve closure from opens to the closure process in, affects the strength gradually increases on the valve seat, namely the shutting down surface and the valve seat by completely are separated from to the contact, and gradually increases the seal to compare the pressure, until completely seals, vice versa. This greatly im-proved the former bll valve seal condition and the seal effect, suits the high tempera-ture high pressure and is easy to crystallize wears the serious situation use. |

|

适用场合 我公司半球阀产品按用途分为:通用阀、管线阀、料浆专用阀、燃气专用阀、石油化工专用阀、煤粉喷吹专用阀六大系列。在石油、化工、冶金、电力、燃气、排灰、喷煤粉等行业是闸阀、截止阀、Y型阀、球阀的更新换代产品。 |

Suitable situation The our company half ball valve product divides into according to the use: the pipeline valve, the material thick liquid special-prupose valve, the fuel gas spe-cial-purpose valve, the petroleum chemical industry special-purpose valve, the pow-dared coal spurt blows the special-purpose valve six big series. In the petroleum, the chemical industry, the metallurgy, the electric power, the fuel gas, the platoon ash,spurt profession and so on powdered coal is the gate valve, the cut-off valve, the Y valve, the ball valve renewal product. |

国标连接及外形尺寸Main conn ection and externaldimensions(mm)

|

公称通径 (DN) |

1.0MPa(GB9113-2000法兰Flange) |

公称通径 (DN) |

4.0MPa(GB9113-2000法兰Flange) |

||||||||||||||||

|

L |

D |

D1 |

D2 |

b |

f |

n-d |

H |

L |

D |

D1 |

D2 |

D3 |

f1 |

b |

f |

n-d |

H |

||

|

50 |

124 |

165 |

125 |

99 |

20 |

2 |

4-18 |

200 |

50 |

124 |

165 |

125 |

99 |

88 |

3 |

20 |

4 |

4-18 |

200 |

|

65 |

145 |

185 |

145 |

118 |

20 |

2 |

4-18 |

215 |

65 |

145 |

185 |

145 |

118 |

110 |

3 |

22 |

4 |

8-18 |

215 |

|

80 |

165 |

200 |

165 |

132 |

20 |

2 |

8-18 |

235 |

80 |

165 |

200 |

165 |

132 |

121 |

3 |

24 |

4 |

8-18 |

235 |

|

100 |

200 |

220 |

180 |

156 |

22 |

2 |

8-18 |

250 |

100 |

200 |

235 |

190 |

156 |

150 |

3.5 |

24 |

4.5 |

8-22 |

250 |

|

125 |

254 |

250 |

210 |

184 |

22 |

2 |

8-18 |

280 |

125 |

254 |

270 |

220 |

184 |

176 |

3.5 |

26 |

4.5 |

8-26 |

280 |

|

150 |

267 |

285 |

240 |

211 |

24 |

2 |

8-22 |

300 |

150 |

267 |

300 |

250 |

211 |

204 |

3.5 |

28 |

4.5 |

8-26 |

300 |

|

200 |

292 |

40 |

295 |

266 |

24 |

2 |

8-22 |

370 |

200 |

292 |

375 |

320 |

284 |

260 |

3.5 |

34 |

4.5 |

12-30 |

370 |

|

250 |

330 |

395 |

350 |

319 |

26 |

2 |

12-22 |

420 |

250 |

330 |

450 |

385 |

345 |

313 |

3.5 |

38 |

4.5 |

12-33 |

420 |

|

300 |

390 |

445 |

400 |

370 |

26 |

2 |

12-22 |

450 |

300 |

390 |

515 |

450 |

409 |

364 |

3.5 |

42 |

4.5 |

16-33 |

450 |

|

350 |

468 |

505 |

460 |

429 |

26 |

2 |

16-22 |

520 |

350 |

468 |

580 |

510 |

465 |

422 |

4 |

46 |

5 |

16-36 |

520 |

|

400 |

526 |

565 |

515 |

480 |

26 |

2 |

16-26 |

570 |

400 |

526 |

660 |

585 |

535 |

474 |

4 |

50 |

5 |

16-39 |

570 |

|

450 |

610 |

615 |

565 |

530 |

28 |

2 |

20-26 |

640 |

450 |

610 |

685 |

610 |

560 |

524 |

4 |

50 |

5 |

20-39 |

640 |

|

500 |

610 |

670 |

620 |

582 |

28 |

2 |

20-26 |

640 |

500 |

610 |

755 |

670 |

615 |

576 |

4 |

52 |

5 |

20-42 |

640 |

|

600 |

762 |

780 |

725 |

682 |

34 |

2 |

20-30 |

720 |

600 |

762 |

890 |

795 |

735 |

675 |

4 |

60 |

5 |

20-48 |

720 |

|

700 |

889 |

895 |

840 |

794 |

34 |

5 |

24-30 |

800 |

700 |

|

|

|

|

|

|

|

|

|

|

|

公称通径 (DN) |

1.6MPa(GB9113-2000法兰Flange) |

公称通径 (DN) |

6.4MPa(GB9113-2000法兰Flange) |

||||||||||||||||

|

L |

D |

D1 |

D2 |

b |

f |

n-d |

H |

L |

D |

D1 |

D2 |

D3 |

f1 |

b |

f |

n-d |

H |

||

|

50 |

124 |

165 |

125 |

99 |

20 |

2 |

4-18 |

200 |

50 |

124 |

180 |

135 |

105 |

88 |

4 |

26 |

3 |

4-23 |

200 |

|

65 |

145 |

185 |

145 |

118 |

20 |

2 |

4-18 |

215 |

65 |

145 |

205 |

160 |

130 |

110 |

4 |

28 |

3 |

8-23 |

215 |

|

80 |

165 |

200 |

165 |

132 |

20 |

2 |

8-18 |

235 |

80 |

165 |

215 |

170 |

140 |

121 |

4 |

30 |

3 |

8-23 |

235 |

|

100 |

200 |

220 |

180 |

156 |

22 |

2 |

8-18 |

250 |

100 |

200 |

250 |

200 |

168 |

150 |

4.5 |

32 |

3 |

8-26 |

250 |

|

125 |

254 |

250 |

210 |

184 |

22 |

2 |

8-18 |

280 |

125 |

254 |

295 |

240 |

202 |

176 |

4.5 |

36 |

3 |

8-30 |

280 |

|

150 |

267 |

285 |

240 |

211 |

24 |

2 |

8-22 |

300 |

150 |

267 |

345 |

280 |

240 |

204 |

4.5 |

38 |

3 |

8-34 |

300 |

|

200 |

292 |

340 |

295 |

266 |

24 |

2 |

12-22 |

370 |

200 |

292 |

405 |

345 |

300 |

260 |

4.5 |

44 |

3 |

12-36 |

370 |

|

250 |

330 |

405 |

350 |

319 |

26 |

2 |

12-26 |

420 |

250 |

330 |

470 |

400 |

352 |

313 |

4.5 |

48 |

3 |

12-36 |

420 |

|

300 |

390 |

460 |

400 |

370 |

28 |

2 |

12-26 |

450 |

300 |

390 |

530 |

460 |

412 |

364 |

4.5 |

54 |

4 |

16-36 |

450 |

|

350 |

468 |

520 |

460 |

429 |

30 |

2 |

16-26 |

520 |

350 |

468 |

600 |

525 |

475 |

422 |

5 |

60 |

4 |

16-41 |

520 |

|

400 |

526 |

580 |

515 |

480 |

32 |

2 |

16-30 |

570 |

400 |

526 |

670 |

585 |

525 |

474 |

5 |

66 |

4 |

16-42 |

570 |

|

450 |

610 |

640 |

565 |

530 |

34 |

2 |

20-30 |

640 |

450 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

500 |

610 |

715 |

620 |

582 |

36 |

2 |

20-33 |

640 |

500 |

610 |

800 |

705 |

640 |

576 |

5 |

70 |

4 |

20-48 |

640 |

|

600 |

762 |

840 |

725 |

682 |

38 |

2 |

20-36 |

720 |

600 |

762 |

930 |

820 |

750 |

675 |

6 |

76 |

5 |

20-58 |

720 |

|

700 |

889 |

910 |

840 |

794 |

40 |

5 |

24-36 |

800 |

700 |

|

|

|

|

|

|

|

|

|

|

|

公称通径 (DN) |

2.5MPa(GB9113-2000法兰Flange) |

公称通径 (DN) |

10.0MPa(GB9113-2000法兰Flange) |

||||||||||||||||

|

L |

D |

D1 |

D2 |

b |

f |

n-d |

H |

L |

D |

D1 |

D2 |

D3 |

f1 |

b |

f |

n-d |

H |

||

|

50 |

124 |

165 |

125 |

99 |

20 |

2 |

4-18 |

200 |

50 |

124 |

195 |

145 |

112 |

88 |

4 |

28 |

3 |

4-26 |

200 |

|

65 |

145 |

185 |

145 |

118 |

22 |

2 |

8-18 |

215 |

65 |

145 |

220 |

170 |

138 |

110 |

4 |

32 |

3 |

8-26 |

215 |

|

80 |

165 |

200 |

160 |

132 |

24 |

2 |

8-18 |

235 |

80 |

165 |

230 |

180 |

148 |

121 |

4 |

34 |

3 |

8-26 |

235 |

|

100 |

200 |

235 |

190 |

156 |

24 |

2 |

8-22 |

250 |

100 |

200 |

265 |

210 |

172 |

150 |

4.5 |

38 |

3 |

8-30 |

250 |

|

125 |

254 |

270 |

220 |

184 |

26 |

2 |

8-26 |

280 |

125 |

254 |

315 |

250 |

210 |

176 |

4.5 |

42 |

3 |

8-34 |

280 |

|

150 |

267 |

300 |

250 |

211 |

28 |

2 |

8-26 |

300 |

150 |

267 |

355 |

290 |

250 |

204 |

4.5 |

46 |

3 |

12-34 |

300 |

|

200 |

292 |

360 |

310 |

274 |

30 |

2 |

12-26 |

370 |

200 |

292 |

430 |

360 |

312 |

260 |

4.5 |

54 |

3 |

12-36 |

370 |

|

250 |

330 |

425 |

370 |

330 |

32 |

2 |

12-30 |

420 |

250 |

330 |

506 |

430 |

382 |

313 |

4.5 |

60 |

3 |

12-42 |

420 |

|

300 |

390 |

485 |

430 |

389 |

34 |

2 |

16-30 |

450 |

300 |

390 |

585 |

500 |

442 |

364 |

4.5 |

70 |

4 |

16-42 |

450 |

|

350 |

468 |

555 |

490 |

448 |

38 |

2 |

16-33 |

520 |

350 |

468 |

655 |

560 |

492 |

422 |

5 |

76 |

4 |

16-48 |

520 |

|

400 |

526 |

620 |

550 |

503 |

40 |

2 |

16-36 |

570 |

400 |

526 |

715 |

620 |

558 |

474 |

5 |

80 |

4 |

16-48 |

570 |

|

450 |

610 |

670 |

600 |

548 |

42 |

2 |

20-36 |

640 |

450 |

|

|

|

|

|

|

|

|

|

|

|

500 |

610 |

730 |

660 |

609 |

44 |

2 |

20-36 |

640 |

500 |

|

|

|

|

|

|

|

|

|

|

|

600 |

762 |

845 |

770 |

720 |

46 |

2 |

20-39 |

720 |

600 |

|

|

|

|

|

|

|

|

|

|

美标连接及外形尺寸Main conn ection and externaldimensions(mm)

|

公称通径 (DN) |

150Lb(ANSI B16.5RF法兰Flange) |

公称通径 (DN) |

4000Lb(ANSI B16.5RF法兰Flange) |

||||||||||||||||

|

L |

D |

D1 |

D2 |

b |

f |

n-d |

H |

L |

D |

D1 |

D2 |

b |

f |

n-d |

H |

||||

|

2″ |

50 |

124 |

152 |

120.5 |

92 |

16 |

1.6 |

4-19 |

200 |

2″ |

50 |

124 |

165 |

127 |

92 |

25.5 |

6.4 |

8-19 |

200 |

|

21/2″ |

65 |

145 |

178 |

139.5 |

105 |

18 |

1.6 |

4-19 |

215 |

21/2″ |

65 |

145 |

190 |

149 |

105 |

29 |

6.4 |

8-22 |

215 |

|

3″ |

80 |

165 |

190 |

152.5 |

127 |

19 |

1.6 |

4-19 |

235 |

3″ |

80 |

165 |

210 |

168.5 |

127 |

32 |

6.4 |

8-22 |

235 |

|

4″ |

100 |

200 |

229 |

190.5 |

157 |

24 |

1.6 |

8-19 |

250 |

4″ |

100 |

200 |

254 |

200 |

157 |

35 |

6.4 |

8-26 |

250 |

|

5″ |

125 |

254 |

254 |

216 |

186 |

24 |

1.6 |

8-22 |

280 |

5″ |

125 |

254 |

279 |

235 |

186 |

38.5 |

6.4 |

8-26 |

280 |

|

6″ |

150 |

267 |

279 |

241.5 |

216 |

26 |

1.6 |

8-22 |

300 |

6″ |

150 |

267 |

318 |

270 |

216 |

41.5 |

6.4 |

12-26 |

300 |

|

8″ |

200 |

292 |

343 |

298.5 |

270 |

29 |

1.6 |

8-22 |

370 |

8″ |

200 |

292 |

381 |

330 |

270 |

48 |

6.4 |

12-29 |

370 |

|

10″ |

250 |

330 |

406 |

362 |

324 |

31 |

1.6 |

12-25 |

420 |

10″ |

250 |

330 |

445 |

387.5 |

324 |

54 |

6.4 |

16-32 |

420 |

|

12″ |

300 |

390 |

483 |

432 |

381 |

32 |

1.6 |

12-25 |

450 |

12″ |

300 |

390 |

521 |

451 |

381 |

57.5 |

6.4 |

16-35 |

450 |

|

14″ |

350 |

468 |

533 |

476 |

413 |

35 |

1.6 |

12-29 |

520 |

14″ |

350 |

468 |

585 |

514.5 |

413 |

60.5 |

6.4 |

20-25 |

520 |

|

16″ |

400 |

526 |

597 |

540 |

470 |

37 |

1.6 |

16-29 |

570 |

16″ |

400 |

526 |

650 |

571.5 |

470 |

63.5 |

6.4 |

20-39 |

570 |

|

18″ |

450 |

610 |

635 |

578 |

533 |

40 |

1.6 |

16-32 |

640 |

18″ |

450 |

610 |

711 |

628.5 |

533 |

67 |

6.4 |

24-39 |

640 |

|

20″ |

500 |

610 |

699 |

635 |

584 |

43 |

1.6 |

20-32 |

640 |

20″ |

500 |

610 |

775 |

686 |

584 |

70 |

6.4 |

24-42 |

640 |

|

24″ |

600 |

762 |

813 |

749.5 |

692 |

48 |

1.6 |

20-35 |

720 |

24″ |

600 |

762 |

915 |

813 |

692 |

76.5 |

6.4 |

24-48 |

720 |

|

28″ |

700 |

889 |

927 |

863.5 |

800 |

72 |

1.6 |

28-35 |

800 |

28″ |

700 |

|

|

|

|

|

|

|

|

|

公称通径 (DN) |

300Lb(ANSI B16.5RF法兰Flange) |

公称通径 (DN) |

600Lb(ANSI B16.5RF法兰Flange) |

||||||||||||||||

|

L |

D |

D1 |

D2 |

b |

f |

n-d |

H |

L |

D |

D1 |

D2 |

b |

f |

n-d |

H |

||||

|

2″ |

50 |

124 |

165 |

127 |

92 |

23 |

1.6 |

8-19 |

200 |

2″ |

50 |

124 |

165 |

127 |

92 |

26 |

6.4 |

8-19 |

200 |

|

21/2″ |

65 |

145 |

190 |

149 |

105 |

26 |

1.6 |

8-22 |

215 |

21/2″ |

65 |

145 |

190 |

149 |

105 |

29 |

6.4 |

8-22 |

215 |

|

3″ |

80 |

165 |

210 |

168.5 |

127 |

29 |

1.6 |

8-22 |

235 |

3″ |

80 |

165 |

210 |

168.5 |

127 |

32 |

6.4 |

8-22 |

235 |

|

4″ |

100 |

200 |

254 |

200 |

157 |

32 |

1.6 |

8-22 |

250 |

4″ |

100 |

200 |

273 |

216 |

157 |

38 |

6.4 |

8-25 |

250 |

|

5″ |

125 |

254 |

279 |

235 |

186 |

35 |

1.6 |

8-22 |

280 |

5″ |

125 |

254 |

330 |

266.5 |

186 |

45 |

6.4 |

8-29 |

280 |

|

6″ |

150 |

267 |

318 |

270 |

216 |

37 |

1.6 |

12-22 |

300 |

6″ |

150 |

267 |

356 |

292 |

216 |

48 |

6.4 |

12-29 |

300 |

|

8″ |

200 |

292 |

381 |

330 |

270 |

42 |

1.6 |

12-25 |

370 |

8″ |

200 |

292 |

419 |

349 |

270 |

56 |

6.4 |

12-32 |

370 |

|

10″ |

250 |

330 |

445 |

387.5 |

324 |

48 |

1.6 |

16-29 |

420 |

10″ |

250 |

330 |

508 |

432 |

324 |

64 |

6.4 |

16-35 |

420 |

|

12″ |

300 |

390 |

521 |

451 |

381 |

51 |

1.6 |

16-32 |

450 |

12″ |

300 |

390 |

559 |

489 |

381 |

67 |

6.4 |

20-35 |

450 |

|

14″ |

350 |

468 |

584 |

514.5 |

413 |

54 |

1.6 |

20-32 |

520 |

14″ |

350 |

468 |

603 |

527 |

413 |

70 |

6.4 |

20-38 |

520 |

|

16″ |

400 |

526 |

648 |

571.5 |

470 |

58 |

1.6 |

20-35 |

570 |

16″ |

400 |

526 |

686 |

603 |

470 |

77 |

6.4 |

20-41 |

570 |

|

18″ |

450 |

610 |

711 |

628.5 |

533 |

61 |

1.6 |

24-35 |

640 |

18″ |

450 |

610 |

743 |

654 |

533 |

83 |

6.4 |

20-414 |

640 |

|

20″ |

500 |

610 |

775 |

686 |

584 |

54 |

1.6 |

24-35 |

640 |

20″ |

500 |

610 |

813 |

724 |

584 |

89 |

6.4 |

24-44 |

640 |

|

24″ |

600 |

762 |

914 |

813 |

692 |

70 |

1.6 |

24-41 |

720 |

24″ |

600 |

762 |

940 |

838 |

692 |

102 |

6.4 |

24-52 |

720 |

|

28″ |

700 |

889 |

1035 |

940 |

800 |

86 |

1.6 |

28-45 |

800 |

28″ |

700 |

|

|

|

|

|

|

|

|

sales@xianfengvalve.com

sales@xianfengvalve.com

在线咨询

在线咨询