结构说明Structre instruction:

1.阀座为镶嵌PTFE或填充PTFE密封圈的刚性浮动阀座,具有双重密封效果,阀座由端部O型圈施加予紧力,

并由浮动阀座的活塞效应达到进出口同时密封,这种双重密封结构使阀体中腔与通道完全隔离,

1.Valve base is trie rigid floating one inlayed or filled with PTFE sealing ring, and tias double sealing effect. Synchronous sealing at

trie inlet and outlet activates thanks to the tension from O ring at the top of valve base as well as the piston effect of floating

valve base.

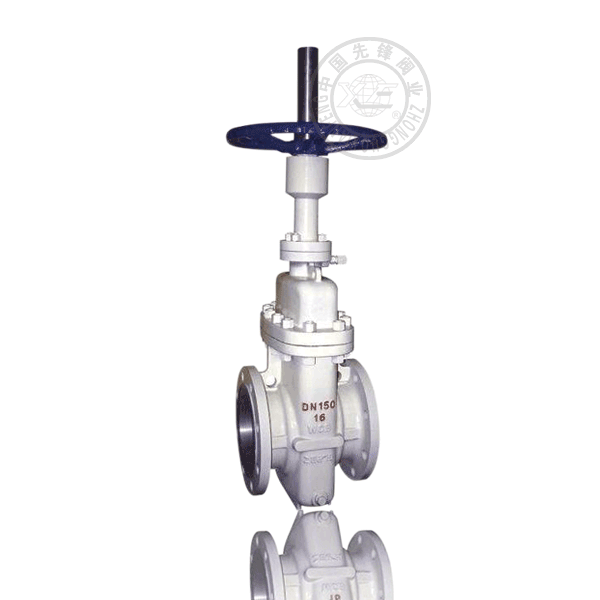

结构说明Structre instruction:

1.阀座为镶嵌PTFE或填充PTFE密封圈的刚性浮动阀座,具有双重密封效果,阀座由端部O型圈施加予紧力,并由浮动阀座的活塞效应达到进出口同时密封,这种双重密封结构使阀体中腔与通道完全隔离,可以在工作状态下检修阀门,排除体腔内残留物。

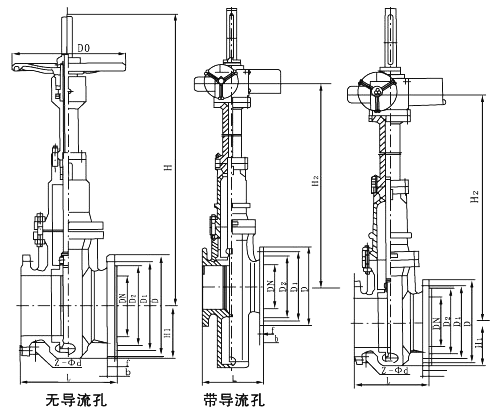

2.闸板为一长方形平行平板,其上开一与通道直径相同的通孔(带导流孔).也可不开孔(不带导流孔).全启时,通道平滑为直管段,流阻系数低,压力损失小,开启与关闭时闸板与阀座始终相互接触,即可擦试附着在密封面间的颗粒污物,又可使密封面不被介质直接冲刷而得到保护。

3.阀杆与闸板采用“Tt,形槽连接;

4.扁体阀门中法兰采用金属柔性石墨垫片,圆体阀门中法兰采用O型密封圈密封:

5.密封面处设有油封装置,紧急状态下可旋紧注脂器注入密封脂以保证密封的绝对可靠;

6.阀门为全封闭式,并在阀盖上端部设有开度指示器,可随时指示阀门的启闭式状态与高度;

7.阀杆、阀座和闸板等零件表面都经过特殊的热处理( MoS2):

8.阀体底部和阀盖上部均设有泄压装置,即可排放脏物,又可排放由于温升等原因造成的升压:

9.手轮顺时针转动为关闭,反之为开启。

1.Valve base is trie rigid floating one inlayed or filled with PTFE sealing ring, and tias double sealing effect. Synchronous sealing at trie inlet and outlet activates thanks to the tension from O ring at the top of valve base as well as the piston effect of floating valve base. This dual-sealing structure is able to completely separate the middle cavity of valve body from the bare, and it is possible to examine and repair the valve under working condition and remove the leftover in body cavity.

2.Flashboard is an oblong parallelflat plate, on which a through hole (with bleed hole) is available with the same diameter of bore. The through hole (without bleed hole) is unnecessary if not required on it. In the state of fully open, smooth bore is a straight pipe with low flow resistance and small pressure loss. Flashboard always keeps connecting wlth valve base wheneverlt Is open or closed, so that the granule dirt stuck on sealing surface can be clean up andthe sealing surface be kept from directly eroding by medium.

3. T type groove connection between valve stem and flashboard.

4. The flange In the flat valve adopts metal soft graphite spacer and the flange in the round valve adopts O sealing rlng for sealing.

5. There is oil seal device on sealing surface. In emergency condition, you may screw filling greaser and inject sealing grease so as to assure absolutelyreliable sealing.

6. Valve is of fully enclosed type. On the upper end of the valve cover, there Is a jaw opening indicator, which can Indicate the state of open and close andheight of valw at any time.

7. The surfaces of valve stem, valve base, flashboard and other parts have been processed through special heat treatment.

8. Pressure release devlces set on the bottom of valve body and the top of the valve cover separately can not only discharge dirt, but also release the rls-ingpressure due to temperature rise and other causes.

9. Close the valve by turning the handwheel clockwise and open on the contrary.

设计、制造标准 Standard for design and manufacture

|

1.设计制造按GB/T12234-89 2.法兰连接尺寸按:JB/T 79-94 3.阀门检查和试验按GB/T 13927-92 |

1.DesignManafacfure According to GB/T 12234-89 2.FlangeDimensionAccording tojB/T 79-94 3.valve Checkand Test Accordingto GB/T 13927-92 |

压力试验Pressure Test

|

压力等级 Pressur Class |

|

工作压力 Working pressure |

||||

|

液体密封 Liquid seal |

气体密封 Gas seal |

壳体强度 Body case Intesion |

气体低压密封 gas at low pressure Seal |

|||

|

公称压力PN(MPa) Nominal pressure |

1.6 |

1.76 |

1.76 |

2.4 |

0.6 |

1.6 |

|

2.5 |

2.75 |

2.75 |

3.75 |

2.5 |

||

|

4 |

4.4 |

4.4 |

6 |

4 |

||

基本型号规格及压力Basic Model,Specification and Pressure

|

常用基本型号 Model |

密封材料代号 Code of sealing material |

公称压力PN Nominal pressure |

||||

|

Flangetype 法兰式 |

手动Manual |

伞齿轮传动 Bevel geal drive |

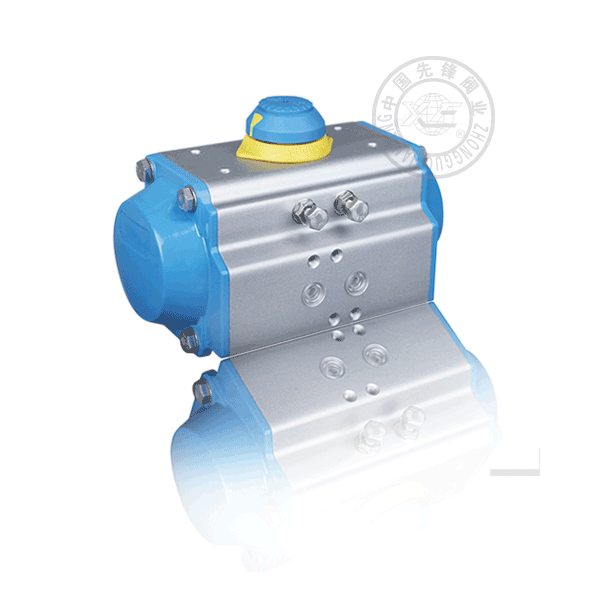

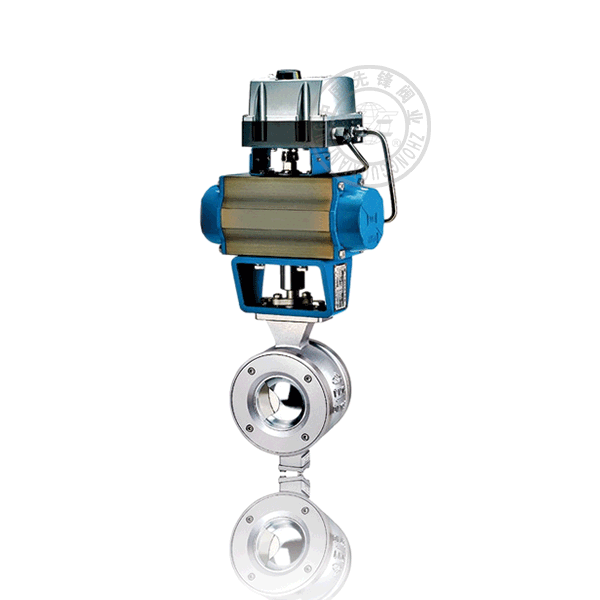

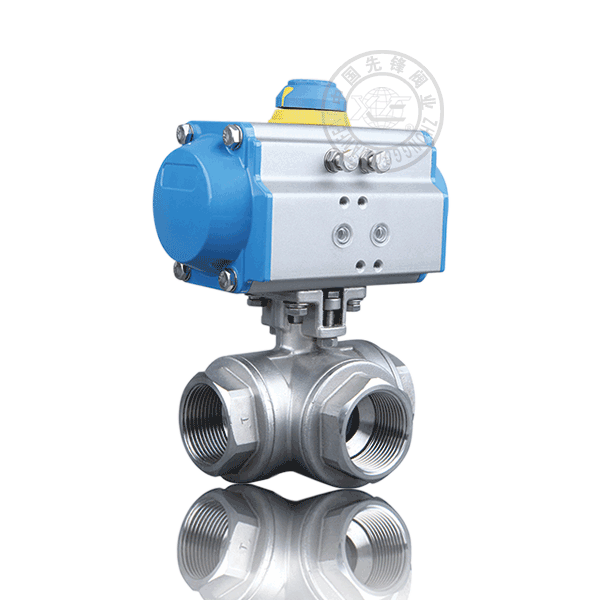

气动 Pneumatic |

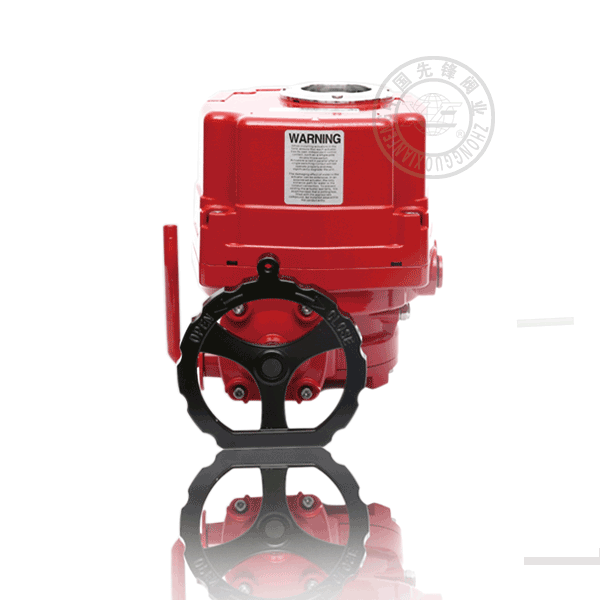

电动Electrinc |

||

|

Z43型 |

Z543型 |

Z643型 |

Z943型 |

F增强聚四氟乙烯 F:Reinforced polytetrafluoroethylene D渗氮钢 D:Nitriding steel H合金钢 H:Alloy steel Y硬质合金 Y:Hard alloy |

1.6~4Mpa |

|

|

Z44型 |

Z544型 |

Z644型 |

Z944型 |

公称通径DNNominal diameter |

||

|

Z47型 |

Z547型 |

Z647型 |

Z947型 |

50~500mm |

||

|

Speclal type 特殊型号 |

Z前加K抗硫阀门 Add K before Z refers to anti-sulfur valve Z前加RQ,燃气 Add RQ before Z refers to combustion gas |

|||||

主要连接及外形尺寸Main connection and extemal dimensions(mm)

|

PN |

DN |

L |

H |

H1 |

H2 |

D |

D1 |

D2 |

b |

f |

Z-φd |

D0 |

|

1.6 (MPa) |

50 |

78 |

415 |

85 |

|

160 |

125 |

100 |

16 |

3 |

4-φ18 |

220 |

|

65 |

190 |

540 |

95 |

|

180 |

145 |

120 |

18 |

3 |

4-φ18 |

250 |

|

|

80 |

203 |

560 |

110 |

|

195 |

160 |

135 |

20 |

3 |

8-φ18 |

250 |

|

|

100 |

229 |

685 |

125 |

|

215 |

180 |

155 |

20 |

3 |

8-φ18 |

300 |

|

|

125 |

254 |

860 |

140 |

|

245 |

210 |

185 |

22 |

3 |

8-φ18 |

320 |

|

|

150 |

267 |

875 |

165 |

|

280 |

240 |

210 |

24 |

3 |

8-φ23 |

350 |

|

|

200 |

292 |

1080 |

190 |

|

335 |

295 |

265 |

26 |

3 |

12-φ23 |

350 |

|

|

250 |

330 |

1360 |

225 |

|

405 |

355 |

320 |

30 |

3 |

12-φ25 |

400 |

|

|

300 |

356 |

1495 |

255 |

1330 |

460 |

410 |

375 |

30 |

4 |

12-φ25 |

500 |

|

|

350 |

381 |

1700 |

265 |

1510 |

520 |

470 |

435 |

34 |

4 |

16-φ25 |

600 |

|

|

400 |

406 |

1950 |

295 |

1700 |

580 |

525 |

485 |

36 |

4 |

16-φ30 |

|

|

|

450 |

432 |

2250 |

325 |

2000 |

640 |

585 |

545 |

40 |

4 |

20-φ30 |

|

|

|

500 |

457 |

2465 |

335 |

2150 |

705 |

650 |

608 |

44 |

4 |

20-φ34 |

|

|

|

600 |

508 |

2680 |

425 |

2800 |

840 |

770 |

718 |

48 |

4 |

20-φ41 |

|

|

|

700 |

610 |

3080 |

455 |

3200 |

910 |

840 |

788 |

50 |

4 |

24-φ41 |

|

|

|

2.5 (MPa) |

50 |

178 |

415 |

85 |

|

160 |

125 |

100 |

20 |

3 |

4-φ18 |

220 |

|

80 |

203 |

530 |

110 |

|

195 |

160 |

135 |

22 |

3 |

8-φ18 |

250 |

|

|

100 |

229 |

692 |

125 |

|

230 |

190 |

160 |

24 |

3 |

8-φ23 |

300 |

|

|

150 |

267 |

875 |

165 |

|

300 |

250 |

218 |

30 |

3 |

8-φ25 |

350 |

|

|

200 |

292 |

1080 |

190 |

|

360 |

310 |

278 |

34 |

3 |

12-φ25 |

350 |

|

|

250 |

330 |

1360 |

225 |

|

425 |

370 |

332 |

36 |

3 |

12-φ30 |

400 |

|

|

300 |

356 |

1495 |

255 |

1330 |

485 |

430 |

390 |

40 |

4 |

16-φ30 |

500 |

|

|

350 |

381 |

1700 |

290 |

1510 |

550 |

490 |

448 |

44 |

4 |

16-φ34 |

600 |

|

|

400 |

406 |

1950 |

330 |

1700 |

610 |

550 |

505 |

48 |

4 |

16-φ34 |

|

|

|

450 |

432 |

2250 |

350 |

2000 |

660 |

600 |

555 |

50 |

4 |

20-φ34 |

|

|

|

500 |

457 |

2465 |

380 |

2150 |

730 |

660 |

610 |

52 |

4 |

20-φ41 |

|

|

|

600 |

508 |

2680 |

425 |

2800 |

840 |

770 |

718 |

56 |

4 |

20-φ41 |

|

|

|

700 |

610 |

3080 |

455 |

3200 |

955 |

875 |

815 |

60 |

4 |

25-φ48 |

|

|

|

4.0 (MPa) |

50 |

216 |

415 |

85 |

|

160 |

125 |

100 |

20 |

3 |

4-φ18 |

220 |

|

80 |

283 |

530 |

110 |

|

195 |

160 |

135 |

22 |

3 |

8-φ18 |

250 |

|

|

100 |

305 |

692 |

125 |

|

230 |

190 |

160 |

24 |

3 |

8-φ23 |

300 |

|

|

150 |

403 |

895 |

165 |

|

300 |

250 |

218 |

30 |

3 |

8-φ25 |

350 |

|

|

200 |

419 |

1080 |

190 |

|

375 |

320 |

282 |

38 |

3 |

12-φ30 |

350 |

|

|

250 |

457 |

1360 |

225 |

|

445 |

385 |

345 |

42 |

3 |

12-φ34 |

400 |

|

|

300 |

502 |

1495 |

255 |

1300 |

510 |

450 |

408 |

46 |

4 |

16-φ34 |

500 |

|

|

350 |

762 |

1700 |

330 |

1510 |

570 |

510 |

465 |

52 |

4 |

16-φ34 |

600 |

|

|

400 |

838 |

1950 |

370 |

1700 |

655 |

585 |

535 |

58 |

4 |

16-φ41 |

|

|

|

450 |

914 |

2250 |

400 |

2000 |

680 |

610 |

560 |

60 |

4 |

20-φ41 |

|

|

|

500 |

991 |

2465 |

440 |

2150 |

755 |

670 |

612 |

62 |

4 |

20-φ48 |

|

|

|

600 |

1143 |

2680 |

425 |

2800 |

890 |

795 |

730 |

62 |

4 |

20-φ54 |

|

sales@xianfengvalve.com

sales@xianfengvalve.com

在线咨询

在线咨询